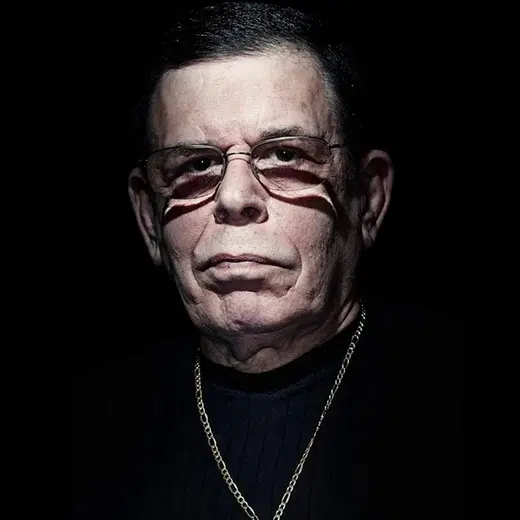

Lake Norden dairy farmer Rodney Elliott displays some of the systems that collect milk during the robotic milking process that was part of a $12 million investment that has improved efficiency and productivity at his farm. Photo by Bart Pfankuch, South Dakota News Watch

By Bart Pfankuch, South Dakota News Watch

Dairy farmer Rodney Elliott stands in a small room where part of his $12 million robotic milking system is doing its job.

The robotic system is located inside a huge new barn on Elliott’s farm northeast of Lake Norden and is one of only a handful of fully robotic milking operations in South Dakota.

As the system functions flawlessly around him — feeding, watering, bedding, washing and milking hundreds of cows day and night with nary a human touch — Elliott watches with a mix of excitement and awe.

“My mother milked cows with just a bucket and a stool,” Elliott said, his Irish accent rising as in song. “We’ve sure come a long way, haven’t we?”

Elliott, 57, is the owner of Drumgoon Dairy, one of the largest and now most technologically advanced dairy farms in South Dakota.

After years of study and hesitance, Elliott made the move into robotic milking in mid-2020 and his first robotic systems launched in late January 2021.

The system seeks to make milking easier and more efficient for farmers but also for cows.

In the system designed by Swedish agricultural manufacturing company DeLaval, about 75 cows are assigned to each milking machine.

Within each robotic system, cows are trained to move on their own through a large rectangular pen split into two sides and outfitted with a series of one-way gates separating areas where they are fed, watered and rested before entering a small gated area where milking takes place. They can be milked up to three times a day.

Cows eat silage placed in reach of their pens and drink water until fully sated. The cows then walk around the end of the rectangle through one-way gates to resting areas where they bed down in sand until their udders are filled with milk. At that point, they feel the need to be milked and make their way one by one to a holding or “perching” area where they await their turn to enter a gated milking chamber known as the “box.”

After a cow enters the “box,” the robotic milking begins.

A robotic arm affixed with a $150,000 high-definition camera swings beneath the cow and its udder full of milk. The camera locates the cow’s four teats, and the robot arm uses a device to wash and dry the teats one by one.

Now that the cow is ready for milking, the robot arm swings back to the milking machine, grabs a suction cup and, with the help of the camera, attaches it to a teat. Once all four cups are attached, milk begins to flow through flexible tubes that carry it to a nearby tank. To prevent any interruptions in the flow of milk, the robotic arm sweeps up the four tubes and holds them clear of the cow’s feet during milking.

When the cow runs dry, the robotic arm removes the cups and returns them to the milking machine, where they are washed clean. The robotic arm swings beneath the cow and uses the camera to locate each teat, which is then given a burst of disinfectant.

A gate in front of the cow opens and she walks forward, making room for another cow that soon enters. During this transition, the robotic arm moves the camera to a sponge and gives the screen a splash of water, a rub on the sponge and and a blast of air to clean and dry it.

A gate at the entry to the box swings open to allow in another cow, and the milking process repeats.

During the six-minute milking process, neither Elliott nor any other farm worker has touched the cows or the milking machine. No one had to position the cow, move her in or out of the machine, pull her back to a pen for food and water or attach any milking cups. Wastes from the cows are scraped by an automatic mechanism that pushes them to a clay-lined earthen pit outside the barn.

After being milked, cows walk through a container of solution that cleans their hooves, and they can lean against a large vertical robotic brush that cleans their hides and scratches any itches.

“It’s called a voluntary milking system and it basically means that the cow can milk herself,” Elliott said. After milking, “she goes back to feed, back to her stall, back to water, then lounges around in a nice sand bed until she feels the need to be milked again.”

Dairy farming and milk collection have undergone increased automation in recent years, said Marv Post, president of the South Dakota Dairy Producers Association.

In most modern dairy farms, cows are backed into pens on a concrete platform that has a channel below it where workers handle the cows and the milking operation.

Post said he has been pleasantly surprised by the effectiveness of robotic milking.

“These barns are amazing,” Post said. “I’m still amazed at how these cows will walk up, get milked, and the next one is ready to come in.”

Post said dairy industry leaders are trying to find funding to support educational programs at South Dakota State University that will train the next generation of farmers in robotics.

The dairy industry in South Dakota is in a mode of rapid expansion to meet a growing need for milk by the burgeoning cheesemaking industry in the state.

Tom Peterson, director of the state dairy association, said the shift to robotic dairy farming is likely to be slow across the industry in South Dakota, mostly because of the large investment needed.

“It all has to pencil out for that to be the route,” Peterson said.

Elliott is a native of Northern Ireland who moved to South Dakota to farm in 2006.

Elliott runs the dairy operation and several associated businesses with his wife, Dorothy, and his two sons.

The financial goals of the robotics are to reduce employee costs and improve milk production of each cow and his herd as a whole. Elliott also sees robotics as a way to improve living conditions for his cows, which live in greater comfort, move about on their own and are handled less amid automation.

His goal was to increase per-cow daily milk production to 75 pounds per cow, and already he has seen 82 to 83 pounds per day from robotic milking. His robotic operation will eventually include about 1,400 cows, still a fraction of his overall operation that has about 6,000 milking cows.

The long-range goal for Elliott is that robotic milking will build a bridge to a brighter future in which his children and other young farmers in South Dakota can enter the dairy industry without the nearly 24/7/365 work and worry that Elliott and other dairy farmers have undergone for generations.

“I feel strongly that the future is going to be trying to find young people who want a better lifestyle than this industry has afforded them so far,” Elliott said, “so they don’t have to do the physical, overnight work because this facility never shuts down.”

Comments